High Precision Lithium Ion Battery Assembly Line Strong

Universality

Battery pack assmbly line equipment introduction

● Cell automatic feeding mechanism: the mechanical arm

automatically grabs the cell and is placed on the specified track.

It is 18-21 in diameter and 65-70 in length.

● Electric core highland barley paper machine: The stepper motor

and cylinder controlled by PLC are used to paste the highland

barley paper on the positive electrode of the finished electric

core. Using a cylinder driven cutter, stamping and pasting four

cells at a time. The sections are made of high speed steel with

high wear resistance.

● Battery sorting machine: It has the function of scanning and data

storage for the battery. 7 sorting gears. Automatic sorting

equipment suitable for various specifications of cylindrical

battery voltage and internal resistance test. It is 18-21 in

diameter and 65-70 in length.

● CCD vision inspection equipment: multi-functional vision

inspection system based on CCD industrial camera and machine vision

technology.

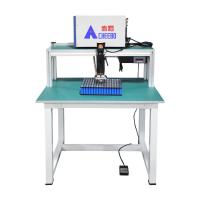

● Battery automatic spot welding machine: suitable for welding

various specifications of cylindrical batteries, using automatic

single-side spot welding welding.

● Fixture rotation system: automatically sensing the fixture to

reach its position, rotating mechanism clamping fixture rotation,

so that the fixture return to the next program.

● The lithium battery pack production line is suitable for the

battery pack assembly production of household appliances/electric

bicycles/power tools/garden tools/energy storage power supplies and

other products.

● Modular design: each device can be automatically connected or

used separately, and can be freely combined and used on demand.

● Lithium battery production line is a multi-axis motion control

system developed by modern automation experts. Automatic mechanism

with precision drive and motor control for real-time and effective

control of automated production equipment.

● Lithium battery assembly line is suitable for 18650, 21700,

26650, 32700 and other cylindrical battery assembly lines.

● The built-in fixture is returned to the track, after the assembly

is completed, the fixture is manually removed and placed on the

return track. The fixture is automatically returned to the previous

station, and the welding track is placed after manual assembly.

Lithium ion battery Production line planning diagram

lithium battery assembly line technical specification

| Work method | Stepper motor + pneumatic | Machine Dimensions | 1275*860*1524MM |

| structural material | aluminium alloy | Machine Weight | 150KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Cylindrical cell sticker |

| Production efficiency | 60-70PPM | Air source specification | 1/CFM |

| Applicable battery specifications | 18650/21700/21650 | Pass rate | ≥95% |

| Sticker efficiency | ≥60PPM | Transmission mode | Mechanical hand |

| Compatible material | Highland barley paper, fast bus paper, glutinous rice paper, RET

protective stickers, etc | Maximum impact speed | 99.99%

|

Battery pack module assembly line Process Introduction

The battery is loaded into the hopper of the paper paste machine →→

Automatically paste the positive electrode

pad sticker →→ the battery automatically enters the separator →→

the separator sweeps the test data for archiving →→

The battery is sent into the corresponding receiving tank → The

workers take out the loading fixture in groups →

push the CCD automatic polarity detection screen → the unqualified

manual correction is automatically sent out →

the workers cover the upper plate of the fixture →→ push the spot

welder Automatic spot welding on side A→→

The machine automatically turns over to side B for welding

completion →→ Take out the welded battery pack fixture

and return it to the frontto enter the next escape ring →→ Install

the BMS board after the battery pack welding

inspection →→Machine or manual welding of the BMS board → Workers

line and install auxiliary materials →→

Test the battery pack parameters fail to pass the inspection. →→

Send aging inspection to aging workshop →→

Packaging workshop packing

lithium battery assembly line process Introduction

1. Battery automatic feeding

2. Positive electrode paste insulated paper machine

3. Cell voltage internal resistance sorting

4. Cell mounting bracket fixture platform

5. CCD detection of positive and negative battery pack

6. Fixture cover top plate platform

7. Spot welding on side A

8. Fixture turning mechanism

9. Side B welding

10. Back-end installation production line

lithium battery assembly line application case

1. Energy storage battery pack 2. Electric bicycle battery pack 3.

Power tool battery pack

FAQ

Q: What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order

of 1 or 100, we will wholeheartedly support you.

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For

the installation of some widgets, we will send out detailed

training videos and user manuals randomly. 95% of customers can

teach themselves.

Q: I don't know which one is right for me?

A: Please tell us the following information

1) Battery model and type.

2) Welding material and welding thickness

3) Commercial industry: We have a lot of sales experience and can

provide you with advice.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on

each unit. After all the tests are passed, our QC will test the

welding performance.

Q: How can I do if the machine goes wrong?

A: If you encounter such problems, please contact us as soon as

possible. Do not try to repair the machine by yourself or others.

We will respond as soon as possible within 24 hours to solve your

problem.

Service process

Pre-sale:

1. Customers send inquiries and inquiries

2. Recommend products according to customer needs

3. Video communication to confirm final requirements

4. Both parties shall deliver the confirmation of technical

specifications

5. Both parties sign the contract

6. Place orders and arrange production in the workshop

7. Arrange delivery

After sale:

1. Confirm whether customers need on-site service or video

communication guidance for debugging equipment.

2. If there is any problem with the equipment, video communication

will be adopted to solve the problem first. Door-to-door service

can be provided if there is no solution.

Looking forward to your consultation, we will provide you with the

best quality service throughout the process!!!